From conception to completion - we've got it covered

With over 30 years experience, we can guide you through the entire production process – from designing initial concepts to manufacturing the finished product.

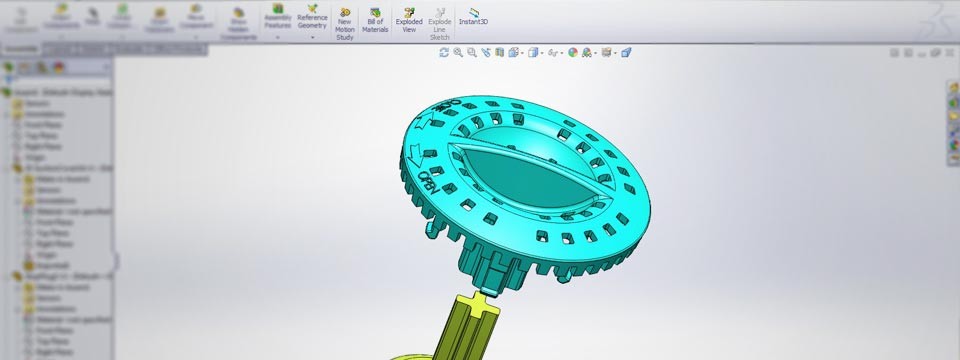

Design

With many years of experience in product development and manufacturing, we can manage your project from conception or turn your finished design into a manufacturable item. No project is too big or too small – we have successfully assisted first time inventors through to multinational manufacturers. Using the latest 3D Design software, we can turn your sketch, model or CAD data into reality.

Prototyping

For many products, prototyping is an important and cost-saving part of the design process. By creating an exact physical replica of the completed computer generated design, it is possible to verify all aspects of the design before undertaking the more expensive tooling process. We are able to supply these replica parts by utilising a number of different methods, including 3D printing, SLA or rapid CNC machining. We will assist you in choosing the correct method for your particular product.

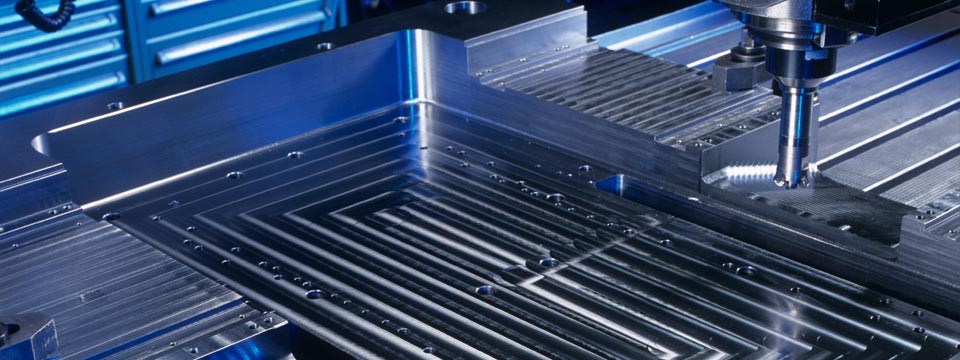

Production Tooling

With over thirty years experience in the manufacture of many types of tooling (including plastic injection, die cast and press tools), we are confident in our ability to provide cost-effective, long-lasting tooling to suit any requirement. Depending on the nature of your project you may wish to have your tooling manufactured here in our Melbourne facility or overseas where it will be managed by our Australian partners in Shenzhen, China. Either way, we are committed to supplying high quality, cost-effective tooling on time.

Production

As well as operating our own plastic injection moulding facility we have worked closely for many years with a wide range of plastic injection moulders, blow moulders, die casters and metal formers both locally and overseas. These relationships mean we are perfectly positioned to either manage the production of your product or refer you to a suitable local or international manufacturer.

About Us

Since establishment in 1992, Norvill Tooling has produced high quality plastic injection dies, press tools and pressure die-cast dies for a wide range of clients. We work with individuals through to large companies involved in a variety of fields including automotive, electronics, homewares and hobbies. Over time, we have developed the business to provide a complete service, from design to manufacture. In addition to our local Toolmaking and Plastic Injection Moulding facility, we now provide high-quality, cost-effective prototyping, tooling and finished products via our Australian partners in Shenzhen, China.

Our Services

We offer a range of services, including:

- CNC Machining

- CNC Wirecutting

- Milling, Turning & Grinding

- Spark Erosion (EDM)

- Jig and Fixture Manufacture

- Short run production machining.

- Plastic Injection Moulding

Contact Us

If you would like to get in touch:

Call: 03 9768 3254

Email: info@norvilltooling.com.au

[google-map-v3 width=”100%” height=”300″ zoom=”13″ maptype=”roadmap” mapalign=”center” directionhint=”false” language=”default” poweredby=”false” maptypecontrol=”false” pancontrol=”true” zoomcontrol=”true” scalecontrol=”false” streetviewcontrol=”false” scrollwheelcontrol=”false” draggable=”true” tiltfourtyfive=”false” addmarkermashupbubble=”false” addmarkermashupbubble=”false” addmarkerlist=”3/6 Swift Way, Dandenong South VIC 3175{}1-default.png{}Norvill Tooling” bubbleautopan=”true” showbike=”false” showtraffic=”false” showpanoramio=”false”]